Nose Gear Systems / Components

EGP Canard Nose Gear Extension/Retraction System

My goal was to create a system that minimized both mechanical modifications to the F-22 and NG-30 structures, allowing for simple retrofit into existing manual or electrical nose gear retract system installations and minimized the changes to the design for new builds. I was able to retrofit my COZY MKIV, which started with a stock manual system and then had an EZNoselift (classic) system for about 20 years, in a few days.

The EGP System uses an OTS (Off The Shelf) electric linear actuator with integral adjustable limit switches, new NG-30 side attachment plates and spacers and a new actuator mounting block. On a COZY MKIV, it fits completely forward of the F-22 bulkhead and in between the outer surfaces of the NG-30s, requiring no F-22 mods or hole. On Variezes, Long-EZs and COZY IIIs it requires a small, non-structural modification to the forward face of F-22. It also requires no modification to the two or three side plate mounting holes in the NG-30s. It does require replacement of the existing NG-3/NG-4 brackets, if you're going to re-use your existing nose gear strut rather than fabricate a whole new nose gear strut assembly.

Here’s an exploded 3D CAD view of the new system:

Pros:

OTS Actuator: No actuator modifications required or performed, therefore no weak points from machining or welding as with existing actuator systems.

No Spring Cartridge: The origin history of the spring cartridge used with manual and electric actuation systems is unknown to me but in my opinion the spring cartridge causes far more problems than it solves (if it solved any). Removing the spring allows for hard braking on short runways or in emergency situations without the danger of nose gear steering axis angle inversion and extreme shimmy. Removal also eliminates the "porpoising" action of the nose of these aircraft when taxiing over bumps or dips, which can find resonance and lead to tipback or prop strikes, aside from merely being annoying and scary to passengers.

There are numerous examples of aircraft with the original VE manual gear, - the ones that Ryszard Zadow recently mentioned on the COBA list, as well as Mehran Salamati in his Berkut(s), along with others who've operated safely for many years with no spring cartridges.Limit switch adjustment: Adjusting the limit switches in the OTS actuator is very simple and the switches are protected with no connectors between them and the actuator itself.

Weight: Approximately the same weight as existing electric actuation systems.

Cost: Final cost will be dependent upon quantity of units purchased, but is almost guaranteed to be equal to or lower than existing, available nose gear retraction systems.

Eliminated Issues :

Loose/bent side plate attachment bolts

Wobbling extension shaft due to poor welding alignment of ball screw shaft

Grinding of bottom of actuator to clear NG-4 interior surface

Wallowing of NG-3/4 mounting holes due to using bolt as the bearing member

Plastic drive gear breakage

Poor / non-existent technical support

Cons:

No Spring Cartridge: If you believe that the spring cartridge allows for taxiing on rougher ground without breakage, then this would be a "con", but that's not a belief to which I subscribe, so for me, this is not a "con".

No Mechanical Extension: As with most (if not all) of the currently available nose gear systems, no manual extension crank is possible - only an electric backup in the case of aircraft electrical system failure is possible.

1,500 lb. Load Limit: Currently available (and previous) systems which used the Thomson Saginaw Ball Screw mechanism had a maximum load capability of approximately 3,000 lb. This was required to lift a MGW, forward CG COZY MKIV from a grazing position to a fully extended position (bumper on the ground is the worst case load). Without major modifications to F-22 I was not able to fit an electric actuator that had a 3,000 lb. load capability and I was not willing to force holes or modifications to F-22.

With the new system's 1,500 load capacity, you will be required to lift the nose to 18" - 24" off the ground before loading the front seat (the amount of load will determine required height - these #'s are approximate).

Since raising a fully loaded aircraft from the ground is contraindicated due to the fact that the NG-1 strut was not designed for such loading, I believe that the advantage of not having to modify the aircraft structure outweighs the disadvantage of having to raise the nose prior to front seat loading.

NOTE: Installation of this system may require reconfiguration of any components you may have mounted in the nose above or forward of the nose gear mechanism/actuator. This may include the battery. If you’re using a large battery, you may need to switch to a smaller battery, such as an Odyssey PC-680 or equivalent, which does fit in the plans battery tray.

Price $2,600 Weight: ~13 lb.

EGP Mechanical/Electrical Installation Instructions - Rev. 8

Installed Actuator:

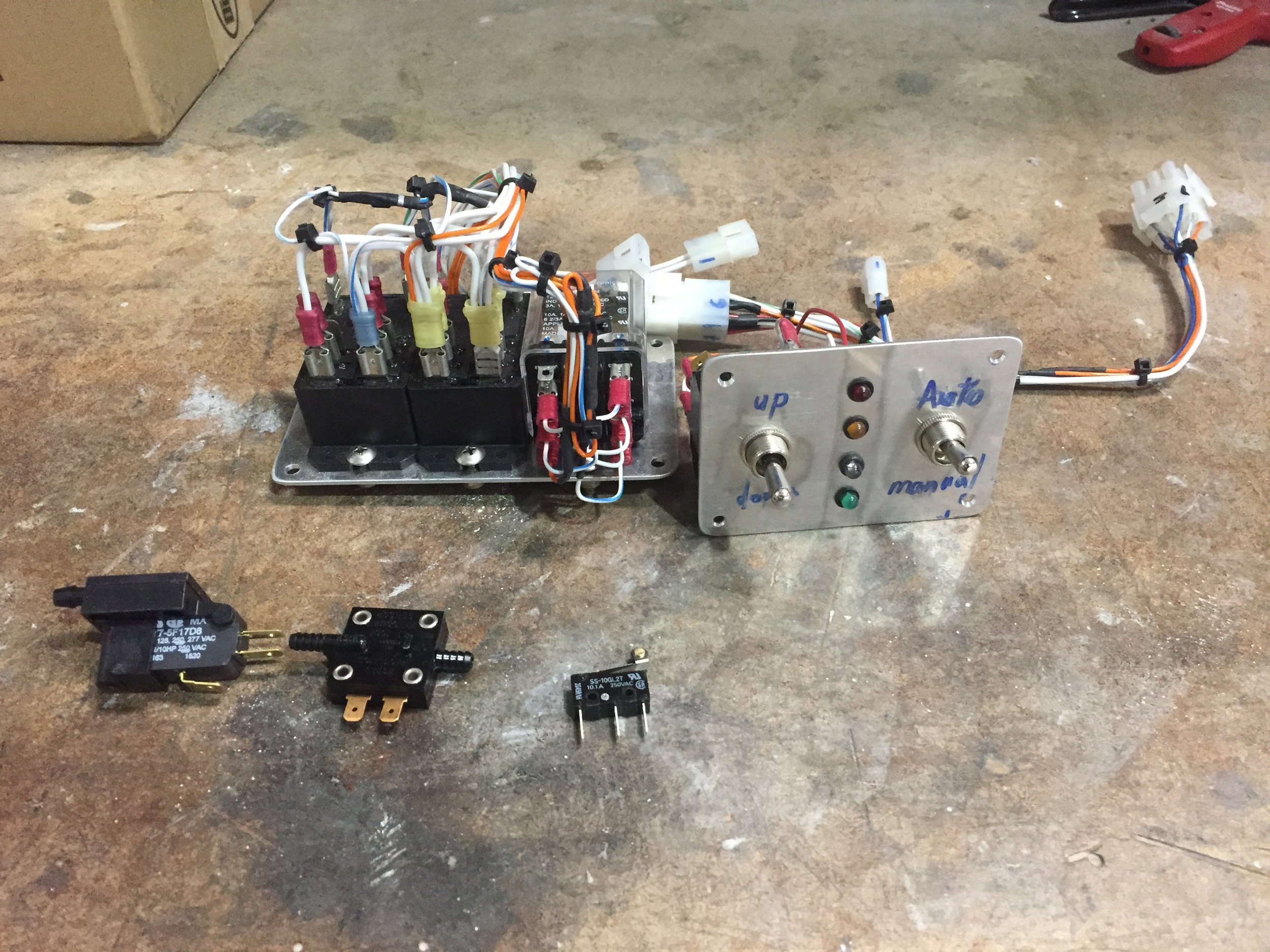

EGP System Electrical Circuitry File Availability:

Electrical Drive for EGP Nose Gear System Schematic Rev. 2 (Reference ONLY)

Thomson K2 Wiring Instructions

EZNoselift System Components:

EZNoselift Clamp System

The EZNoselift system used in many canard aircraft has a number of basic design flaws, one of which leads to the unit attempting to unscrew the trunnion pin attach bolts (the AN5-12A or AN5H-12A bolts through the side mounting plates) every time it's actuated. Sometimes, the unit succeeds in unscrewing the bolts completely and sometimes only partially, which then sometimes leads to bent bolts and/or the unit damaging the mounting plates and trunnion pin, as well as possibly causing collapse of the unit. The method of mounting of the bushings in the side plates puts the bolts in bending, rather than pure shear, which is why they sometimes bend.

This clamp system may be retrofitted onto any Original EZNoselift system of any vintage, and usually to the newer, belt drive version of the EZNoselift, without any changes to the aircraft structure or EZNoselift side mounting plates.

This system clamps on the exterior of the upper tube and supports the shear pins so that they cannot stress, bend or deform the bolts, nor is tension on the bolts required to prevent the bolts from loosening.

Price: $350 + S&H Clamp System Installation Instructions - Rev. 5

EZNoseLift AutoExtend Circuit Information

The AEX (AutoExtend) system provided by EZNoselift is driven only by IAS, so will extend the nose gear in multiple situations in which extension is not warranted or desired. In addition, the wiring harness provided by EZNoselift is inadequate with respect to reliability, robustness, and voltage drop (due to wire gauge and length issues). To correct these deficiencies, I’ve created a wiring schematic for an electrical drive system that provides for proper current carrying capacity, backup battery driven extension in the case of full electrical system failure, as well as a robust AEX system using throttle setting, low and high IAS limits, and if desired, a laser altimeter to ensure that the nose gear will only extend automatically when actually attempting to land and the pilot forgets to extend the nose gear.

Along with this information, Trevor Howard has implemented this system (with more capability) on a PC board, with Arduino inteface functions.

File availability is as follows:

Trevor Howard Package ZIP file

Discrete Circuit Schematic - Rev. 2

Discrete Circuit Schematic - Rev. 2a

Discrete Circuit Bill Of Materials - Rev. 5

Other Nose Gear System Components:

NG-2B Foot

High quality, 304SS replacement for the Varieze, Long-EZ and COZY III NG-2 or NG-2A foot. Also fits the 3:23 Composites NG-15X and MKNG-15X Nose Gear Fork Assembly.

Designed to ensure 180 degree free swiveling capability of the canard nose wheel without interference. Thicker base for enhanced robustness.

Price: $125 Installation Instructions - Rev. 2

MKNG-2B Foot

High quality, 304SS replacement for the original COZY MKIV MKNG-2 or MKNG-2A foot with 1/4” mounting screws/bolts. This will not work with the 3:23 Composites NG-15X and MKNG-15X - only with the original wider forks/castings.

Designed to help provide 180 degree free swiveling capability of the canard nose wheel without interference. Thicker base for enhanced robustness.

Price: $150 Installation Instructions - Rev. 2

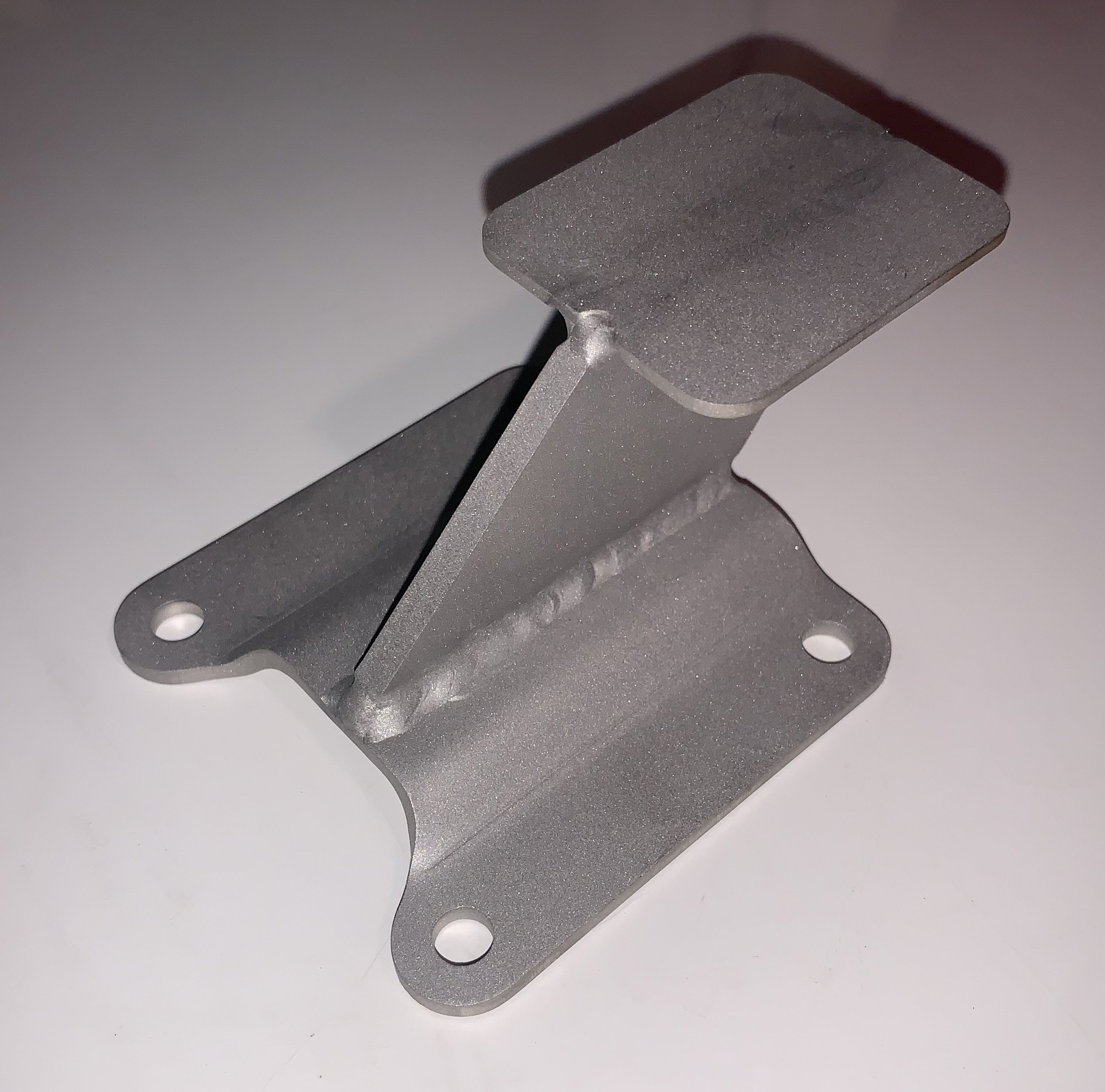

NG-3AA External Bracket

External Nose Gear Strut Bracket for use with the legacy EZNoselift or Wright Nose Lift Systems. May work with other, one off Nose Lift systems as well, but no guarantees.

This is a robust bracket that fits around the NG1-L nose gear strut; mates perfectly with the internal NG-4AA bracket and comes pre-drilled to match the NG-4AA for perfect alignment and jigging during assembly.

Price: (TBD) (Use Plans or existing nose lift instructions for installation)

NG-4AA Internal Bracket

Internal Nose Gear Strut Bracket for use with the legacy EZNoselift or Wright Nose Lift Systems.

This is a robust bracket which mates perfectly with the external NG-3AA bracket. It comes pre-drilled to match the NG-3AA for perfect alignment and jigging during assembly.

Price: (TBD) (Use Plans or existing nose lift instructions for installation)

NG-3B External Bracket

External Nose Gear Strut Bracket only for use with new “EGP Actuator System” - this will not work with the EZNoselift or Wright Nose Lift Systems.

This is a robust bracket that actually fits around the NG1-L nose gear strut; mates perfectly with the internal NG-4B bracket and comes pre-drilled to match the NG-4B for perfect alignment and jigging during assembly.

Price: $50 - Also Included with EGP System Order

Installation Instructions - Rev. 5

NG-4B Internal Bracket

Internal Nose Gear Strut Bracket only for use with new “EGP Actuator System” - this will not work with the EZNoselift or Wright Nose Lift Systems.

This is a robust bracket which mates perfectly with the external NG-3B bracket. It comes pre-drilled to match the NG-3B for perfect alignment and jigging during assembly.

Price: $50 - Also Included with EGP System Order

Installation Instructions - Rev. 5

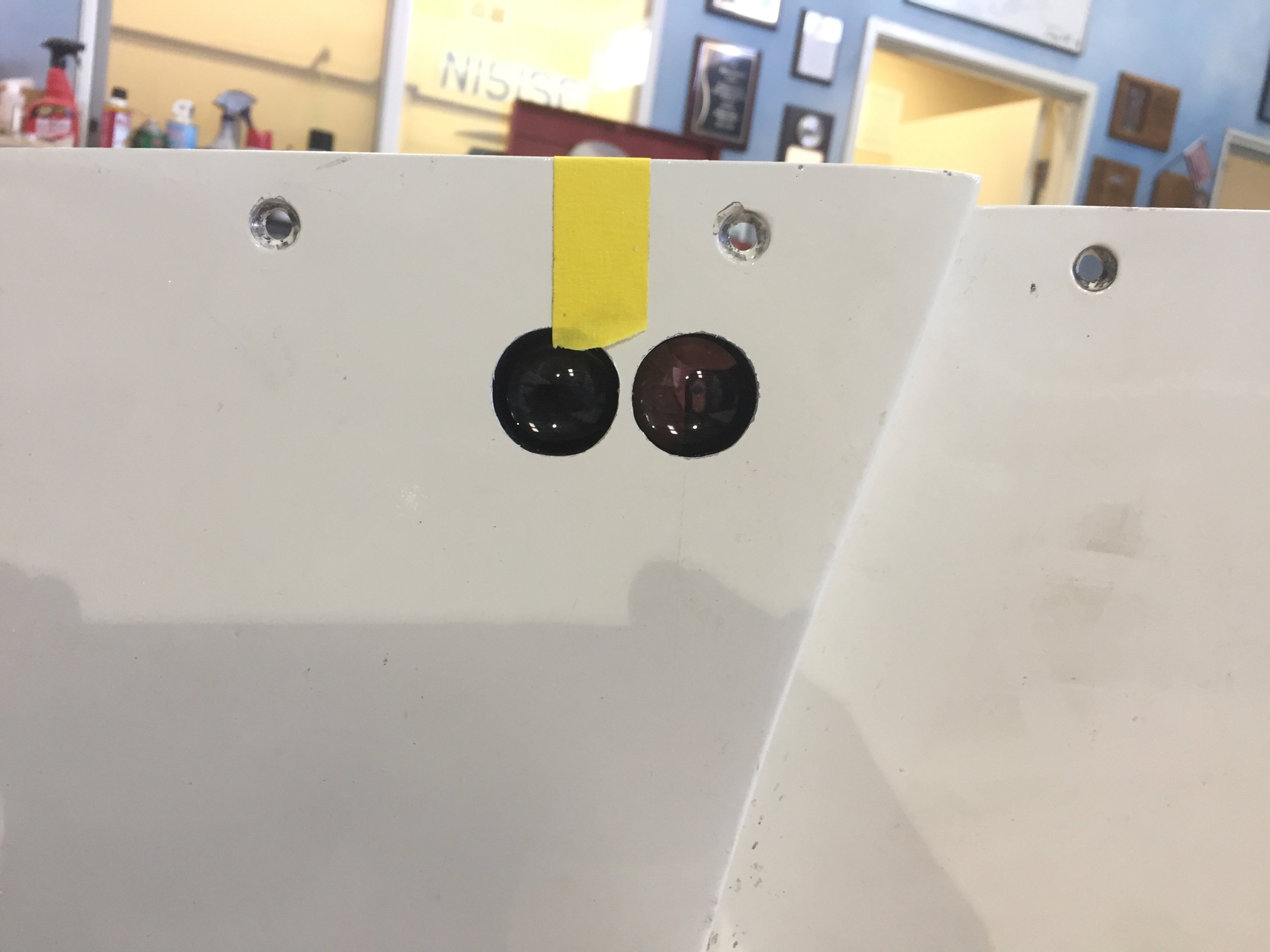

NG-5B Clamp Plate

1/4” thick Aluminum clamp plate - clamps the nose gear strut to the Nose Gear Pivot. Comes pre-drilled to match the NG-6B and MKNG-6B Pivot Housing mounting holes - will not work with older versions of the NG-6 / MKNG-6. With rear edge radii, front corner chamfer and upper hole countersinks.

Price: $50 - Also Included with ( and only for use with) NG-6B / 7B and MKNG-6B / 7B order

Installation Instructions combined with appropriate NG-6B / MKNG-6B Instructions

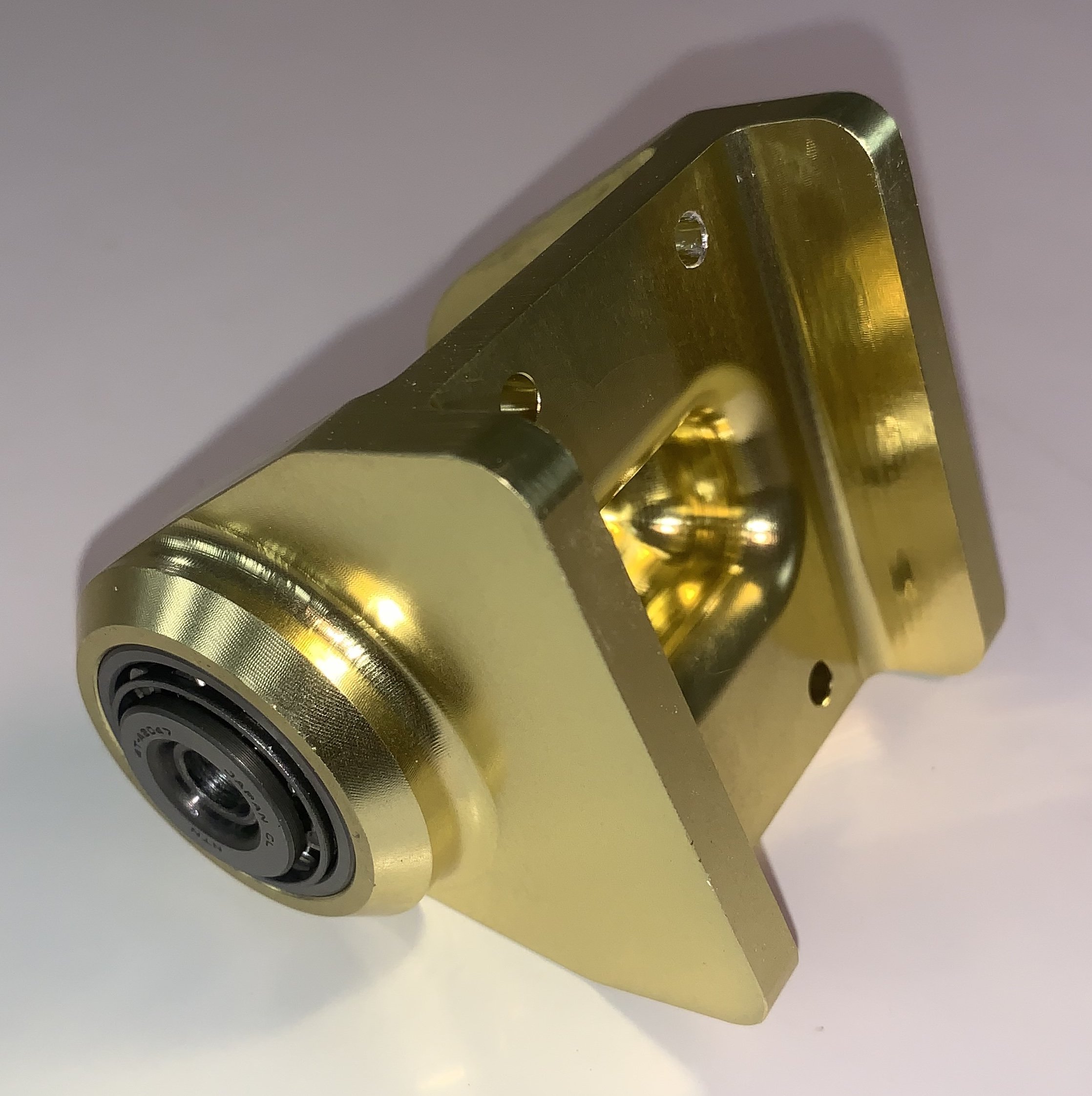

NG-6B / NG-7B Pivot Housing and Spacer

Billet machined aluminum Nose Gear Strut Pivot Housing with steel spacer and tapered roller bearings. Provides robust, smooth operation with no wear. Comes pre-drilled with strut mounting holes to match NG-5B.

This unit is for Varieze, Long-EZ and COZY III nose gear strut mounting. Does not fit COZY MKIV NG-30 spacing.

Price $400 - NG-5B and NG-7B Included with order

NG-6B / NG-7B / NG-5B Installation Instructions Rev. 6

MKNG-6B / MKNG-7B Pivot Housing and Spacer

Billet machined aluminum Nose Gear Strut Pivot Housing with steel spacer and tapered roller bearings. Provides robust, smooth operation with no wear. Comes pre-drilled with strut mounting holes to match NG-5B.

This unit is for COZY MKIV nose gear strut mounting only. Does not fit Varieze, Long-EZ, or COZY III NG-30 spacing.

Price $425 - NG-5B and MKNG-7B Included with order

MKNG-6B / MKNG-7B / NG-5B Installation Instructions Rev. 5

Last Modified: 4/23/2025 - Updated EGP Instructions to Rev. 8; Updated NG3/4 instructions to Rev. 5